Stainless steel pipe the output of a day

[introduction] buy stainless steel pipe equipment a issue for us: how much is the equipment? Second, how about the quality, production can achieve? The two problems are basically all customers are more concerned about the focus of, so the output of a stainless steel tube machine a day is how many?

Buy stainless steel pipe equipment A issue for us: one is how much is the equipment? Second, how about the quality, production can achieve? The two problems are basically all customers are more concerned about the focus of, so the output of a stainless steel tube machine a day is how many?

Actually, see how much is the output of stainless steel tube machine one day, there are many influence factors in the inside, what factors?

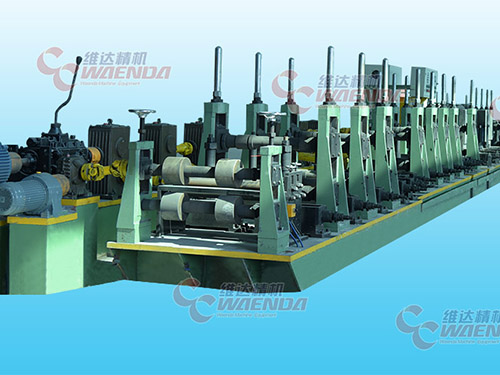

One, the quality of the stainless steel tube machine equipment

Good quality is the absolute principle, a poor quality equipment to high yield coefficient that is has the certain difficulty. Good equipment in terms of speed of power, performance, such as more than a lot better than the general equipment, the speed of the pipe is relatively much faster.

Second, the material of raw materials

The speed of the material of raw material for pipe, production has a certain influence. Good material of stainless steel strip, steel pipe is smooth, basically, a roll of belt material shelf after automatic tube, don't have to worry about. Bad pick-up in the pipe will have some bad influence, can sometimes lead to pipe perforation, welding does not reach the designated position, molting, often cut by material, affect the production progress, some also can lead to injury problems, such as mold. Tubing for pipe to the thickness of the tube speed also has certain influence. In general, the speed of light pipe is faster than thick material, the number of pipes to more, and speed of the thickness control tube is relatively slowly, the number of pipes, there would be less, but the weight is heavier than thin.

Third, the machine is not fixed, often change the mould

For a tube machine, change mould is very often affect its service life, but also affect the production schedule, waste pipe. If long-term fixed a system model of pipe system, pipe production will increase a lot, the waste pipe rate will be greatly reduced. For eliminating the adjustable machine commissioning of raw materials. You want to know, a device, turn again, especially those who just finished thick thin material master switch the machine machine technology requirement is high, if the machine master the technology does not reach the designated position can produce a lot of tuning machine waste, greatly wasted raw material utilization, reduce production.

Four, adjustable machine master and master boot

The output of stainless steel pipe not only related to the equipment of raw materials, and the machine is also linked to the master and the master boot, and the relationship is important! Master good tuning machine technology for the machine tube controls the ability is very good, very little pipe waste production, and good master boot with its boot experience, can be found to solve the problems in the production process, so as not to waste a lot of waste of raw materials is made of!

Five, the welding machine

Stainless steel pipe is through the mechanism of argon arc welding for pipes, so the configuration of high-end welding machine is the key to increase production. Pipe-maling machine equipment speed adjustable came up, raw material also is very good, staffing and experienced return, so, the most important thing now is welded pipe welding machine to deserve them! Only cooperate well, all aspects of the quality of the pipes and output must come on!

QR code

QR code