Stainless steel welded pipe inside and outside the weld line leveling device

Stainless steel welded pipe in the material and mechanical properties are better than stainless steel seamless pipe, but the stainless steel welded pipe inside and outside the weld, especially in the weld more than the removal of the problem has been plagued by stainless steel pipe production enterprises. Although the built-in scraper or internal mill device and other solutions, but the effect is not ideal. Which seriously hindered the further development of stainless steel pipe applications. At present, oil, chemical, nuclear power, boilers, food, medicine and other industries are mainly stainless steel seamless tube。

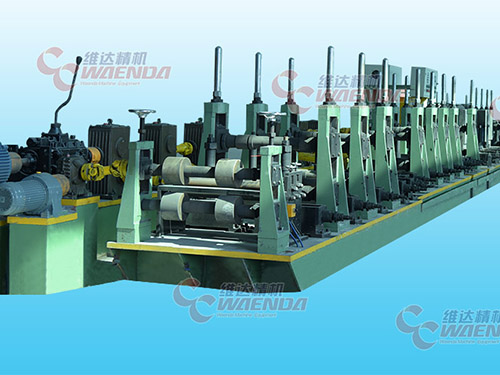

two.Equipment composition

Inside and outside the weld leveling rack a hydraulic pneumatic system with PLC control of the automatic electro-hydraulic control system also includes mold and rolling fluid circulation equipment。

three.Equipment technical characteristics

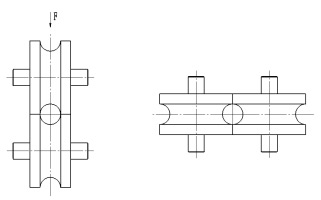

Stainless steel welded pipe inside and outside the weld leveling device is a built-in mandrel and the use of rollers on the stainless steel pipe rolling reciprocating automatic rolling device, by controlling the rolling strength and pass to achieve the stainless steel pipe inside and outside the weld leveling, thoroughly Remove the inside and outside the weld is too high and the requirements of the base metal flush, popular speaking, is to achieve seamless stainless steel pipe。

The drawing part of its equipment is shown below:

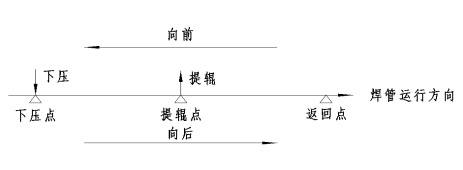

With more than the inside and outside the weld of stainless steel welded pipe through the horizontal roller rolling, the more high is removed, the pipe section into a horizontal oval, the mandrel in the pipe was followed by the main pipe to follow the pipe: The cross section becomes a perfect circle, the mandrel is separated from the pipe by the cylinder back to the proper position when the machine is returned, and then the second rolling cycle。

The reciprocating trajectory is as follows:

三、IGBT on - line bright solution treatment device

The development of stainless steel welded pipe, especially industrial stainless steel pipe, is supported by national industrial policy. However, most of the solid solution treatment process of stainless steel welded pipe adopts online black solid solution and then pickling or off-line bright solution. The former brings environmental problems, And

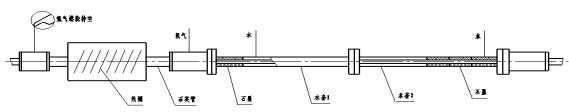

Improve the weld structure and eliminate stress to enhance the corrosion resistance; with hydrogen as a protective gas can be solid solution after treatment of the welded pipe becomes bright and speed up the cooling rate. The cooling of the stainless steel pipe after heating to the solution temperature is carried out by indirect cooling to keep the pipe bright。

Stainless steel welded pipe on-line bright solution of the process of heating and cooling diagram is as follows:

A schematic diagram of an industrial stainless steel pipe production line equipped with an on-line bright solution solution:

1、Two-way swing-type loading frame 2、Forming unit 3、welder 4、Electric control box

5、Welding machine seat 6、Inner bead handling device 7、Weld grinding device 8、Initial sizing device

9、Steel pipe cleaning device 10、Online bright solution treatment device 11、Electro - melting device electrical control system

12、IGBT frequency power cabinet 13、Final diameter and straightening units 14、Automatic cut - off system for steel pipe

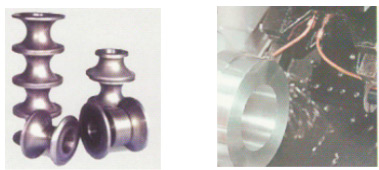

I plant the production of stainless steel profiles all the use of high-quality mold steel Cr12MoV or D2 steel as raw materials, and precision machining (VAD / CAM) and special treatment, high precision, long life。

Available from the mold specifications: from Φ4 to Φ325 within a variety of round tube, square tube, rectangular tube and shaped tube mold。

The machine is used for the grinding and polishing of the outer surface of the stainless steel tube, and it is dryly polished with 8 grinding head or 10 grinding head. The surface roughness of the workpiece is up to Ra0.8μm。

The machine can also be used for other materials of circular pipe surface polishing。

The machine is used for grinding and polishing the outer surface of stainless steel square and rectangular pipe. It is divided into 16 sections, 24 sections, 28 sections, 32 sections and 36 sections。

Seven, flower machine

Available models are 25, 51, 76, 114 type。

Address: Chenzhou City Economic and Technological Development Zone Shigai Tong Industrial Park.

Contact: Mr. Zeng(13807358095)

telephone / fax: 0735-2791118/2791333

Website: www.waenda.com.

E-mail: waenda_machine@188.com

QR code

QR code