Telehone

+86-138-0735-8095

Headquarters Address:Shigaitan Industrial Park,Chenzhou Economic & Technological Development Zone,Hunan,China

Mobil:+86-13807358095

TEL/FAX:+86-0735-2791118 2791333

E-mail:waenda_machine@188.com

Existing WD25-100 type specifications series stainless steel pipe production line can produce Φ4-Φ325 variety of round, square, giant tube-shaped and profiled.

| WD25 | WD40 | WD50 | WD60 | WD90 | |

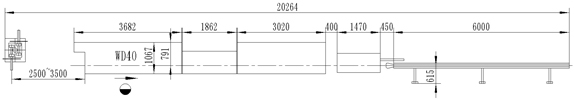

| Machine dimensions | 15.38×1.27×1.70 | 20.26×1.41×1.76 | 21.52×1.55×1.86 | 23.33×1.66×1.90 | 27.20×3.42×2.00 |

| Host size(m) | 5.12×0.83×1.70 | 8.65×1.24×1.76 | 9.87×1.30×1.86 | 11.25×1.48×1.84 | 17.52×2.22×1.80 |

| Machine weight(T) | ≈3.2 | ≈6.0 | ≈9.0 | ≈11.5 | ≈28 |

| Main drive motor power(kw) | 4 | 4/5.5 | 7.5/7.5 | 11/15 | 18.5/22 |

| pipe making range(mm) | Φ8-Φ20 | Φ12.7-Φ50.8 | Φ38.1-Φ76.2 | Φ50.8-Φ114 | Φ114-Φ219 |

| Pipe thickness(mm) | 0.2-0.8 | 0.3-2.0 | 0.5-2.5 | 0.7-3.0 | 1.5-5.0 |

| Welding speed(M/Min) | 4-15 | 0.8-12 | 0.6-10 | 0.5-6 | 0.4-5 |

Stainless steel pipe production line equipped with inside weld bead remover and IGBT bright annealing device

Inside weld bead remover online

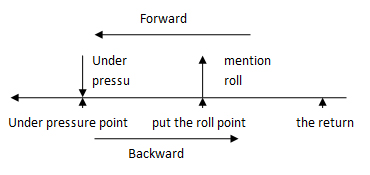

The interal and external weld excess height of the stainless steel TIG pipe would be removed while pipe has been rolled by the horizontal rolls,and rolled into a horizontal oval cross-section,the mandrel is stuck in the pipe to move along the pipe:after rolled by the vertical rolls,pipe cross-section changed into a perfect circle,then the mandrel will be separated from the pipe and returned back to the proper position through the air cylinder pull,at the same time the rolls stand also returned back to a proper position through the hydraulic pull,and then starting a second rolling cycle.

Its reciprocating motion trajectory is as below:

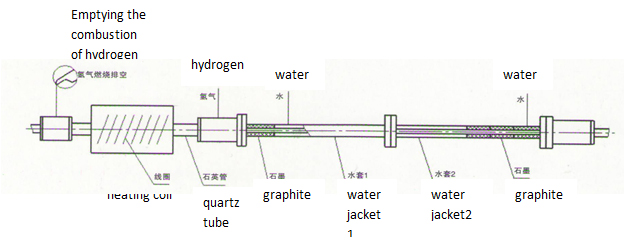

IGBT bright annealing device online

The schematic diagram about the process of heating and cooling for the pipe in the IGBT bright annealing device online

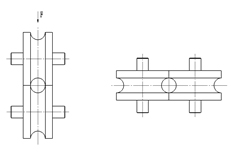

Stainless steel profile die (rolls)

Flower pipe machine

Stainless steel flower pipe machine known as gourd pipe, stainless steel decorative profiles

indispensable accessories. Available models are 25 type, 51 type, 76 type, 114 type.

|

Model Paramater |

HG25 | HG51 | HG76 | HG114 |

| Die size (mm) | 35×300×55 | 50×300×75 | 70×400×60 | 90×650×70 |

| processing range (mm) | Φ12~Φ25 | Φ12~Φ51 | Φ25~Φ76 | Φ38~Φ114 |

| the wall thickness (mm) | 0.25~0.5 | 0.3~1.2 | 0.7~1.5 | 0.7~1.5 |

| the formation length (mm) | 290 | 290 | 260 | 600 |

| the formation time (s) | 3~12 | 3~12 | 8~30 | 10~40 |

| reducing wedge stroke (mm) | 180 | 200 | 250 | 450 |

| the amount of mold opening and closing (mm) | 28 | 30 | 40 | 50 |

| the main motor (KW) | 3 | 4 | 7.5 | 11 |

| spindle speed (rpm) | 300 | 200 | 200 | 200 |

| the spindle center height (mm) | 800 | 800 | 800 | 900 |

| total weight (kg) | ≈1100 | ≈2000 | ≈3000 | ≈5000 |

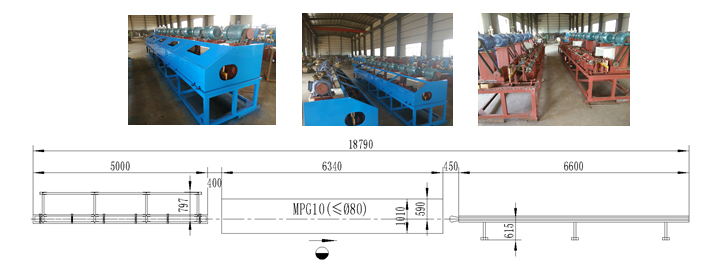

This machine is used for stainless steel tube outer surface polishing, take eight or 10 grinding dry grinding polishing, the surface roughness after polishing machine up Ra0.8μm. The machine can be used for circular outer surface of the pipe polishing other materials.

| POLISH MACHINE | Round polishing machine | ||

| MODEL | PG 10 | MPG10 | LPG10 |

| MACHINE DIMENSIONS(mm) | 18.80×1.42×1.33 | 18.80×1.42×1.33 | 19.10×1.52×1.40 |

| Host size(m) | 6.34×1.10×1.33 | 6.34×1.10×1.33 | 6.34×1.45×1.40 |

| Driving motor/output (KW) | 2.2 | 2.2 | 2.2 |

| Polishing head motor/output (KW) | 5.5(10 PCs) | 5.5(10 PCs) | 5.5(10 PCs) |

| Spindle shaft diameter(mm) | Φ25 | Φ36 | Φ36 |

| Capabilities of Manufacturing | |||

| Max. OD in MM | 50.8 | 80 | 114.0 |

| Min. OD in MM | 12.0 | 31.8 | 50.8 |

| Max Thickness in mm | 2.0 | 3.0 | 3.0 |

| Min. Thickness in mm | 0.3 | 0.3 | 0.6 |

| Max length in meters | 6.0 | 6.0 | 6.0 |

| Min length in meters | 4.0 | 4.0 | 4.0 |

| Speed(m/min about) | 18~24 | 18~24 | 18~24 |

| machine weight (KG) | ≈3.5 | ≈4.0 | ≈6.0 |

| equipped with abrasive size (mm) | maximum diameterΦ400mm,the smallest boreΦ36mm | ||

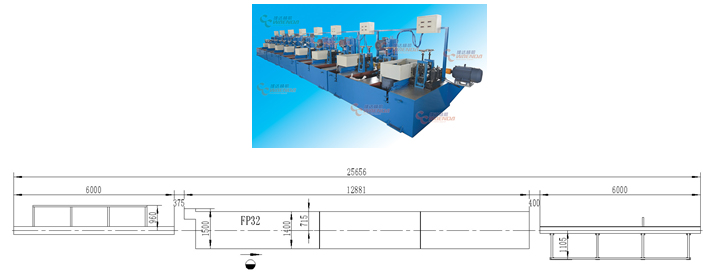

POLISH MACHINERound polishing machine

This pipe outer surface polishing machine is divided into sixteen, twenty four, thirty two or thirty six stages as required surrounded by a combination of polishing spares

| POLISH MACHINE | Square polishing machine | Square polishing machine | Square polishing machine | Square polishing machine |

| MODEL NUMBER | FP16 | FP24 | FP32 | FP36 |

| MACHINE DIMENTIONS(mm) | 19.84×2.07×1.72 | 22.84×2.07×1.72 | 25.67×2.07×1.72 | 27.33×2.07×1.72 |

| Host size(m) | 7.06×1.51×1.72 | 10.06×1.51×1.72 | 13.08×1.51×1.72 | 14.56×1.51×1.72 |

| Driving motor/power (KW) | 4 | 4 | 4 | 4 |

| Polishing head motor/power(KW) | 5.5(16PCS) | 5.5(32PCS) | 5.5(32PCS) | 5.5(36PCS) |

| Spindle shaft diameter(mm) | Φ36 | |||

| Capabilities of Manufacturing | ||||

| Max. OD in MM | 100×100 | 100×100 | 100×100 | 100×100 |

| Min. OD in MM | 10×10 | 10×10 | 10×10 | 10×10 |

| Max Thickness in mm | 3 | 3 | 3 | 3 |

| Min. Thickness in mm | 0.3 | 0.3 | 0.3 | 0.3 |

| Max length in meters | 6 | 6 | 6 | 6 |

| Min length in meters | 3 | 3 | 3 | 3 |

| Speed(m/min) | 18~24 | 18~24 | 18~24 | 18~24 |

| machine weight (kg) | ≈6000 | ≈9300 | ≈12300 | ≈138000 |

| equipped with abrasive size (mm) | maximum diameterΦ400mm,the smallest boreΦ36mm | |||

TEL0086-138-0735-8095

QR code